| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Click on a name below to visit that member's shop. | |||||||

|

|||||||

| Mike Jones (back to top) |

|||||||

|

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

|

|||||||

| Steve Kern (back to top) |

|||||||

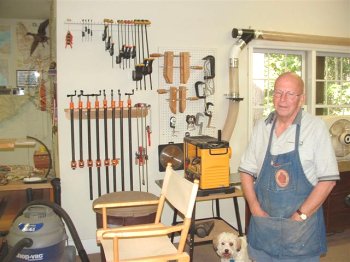

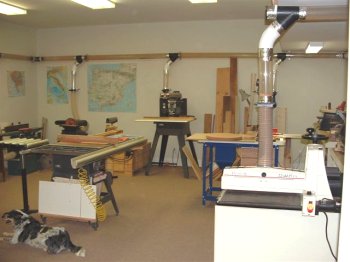

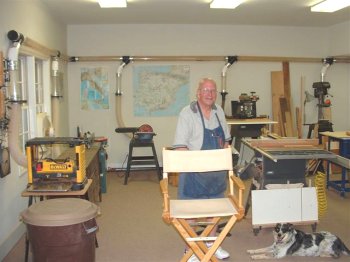

| Steve Kern, a former (and often) President

of the Greenville Woodworker's Guild, has one of the more impressive and

functional workshops in our Guild. Steve inherited an out-building when he

purchased his home off Highway 14 and Roper Mountain Road several years ago,

and has converted a basic building of nearly 1,000 square feet into what

most of us would consider a dream workshop. Equipped with a mini-lathe for pen turning, a 36-inch Jet lathe, horizontal drum sander, 6-inch jointer, scroll saw, two table saws (one is a contractor saw, one a Delta Unisaw), a personally designed and hand-crafted router table, oscillating spindle sander, two drill presses (one a table model), miter saw, and a variety of hand power tools. Nearly all of his power tools are on casters to allow maximum flexibility of his existing space. He has an array of clamps to fix nearly every need, and jigs to support a myriad of operations, including a well designed wooden veneer press. Hard to believe it, but he actually owns a hand plane as well! Steve's workshop has a well-designed 1 and 1/2 hp shop vac that delivers a 1100 cfpm capability. Even though his power tools are portable, he has fixed dust collection stations for each tool, and his individual gates give him ultimate control of his dust collection system. Steve says that keeping his shop environmentally friendly is done primarily through construction of his walls and ceiling. The shop is completely insulated, without windows, and the summer temperatures never exceed 80 degrees. However, he does have a fixed place gas heater attached to his ceiling to help with the winter chill. Lighting is all ceiling mounted with 11 fixtures providing near daylight conditions. Electrical power is provided through a separate panel giving him both 110 and 220 single-phase power. Steve's supply of wood on hand is significant. He keeps ready approximately 2 - 3,000 square feet of lumber, plus storage for another 300 feet of plywood. Since Steve specializes in crafting furniture pieces, he has accumulated mostly hardwoods and a beautiful supply of walnut. He will not need to make a trip to the lumber yard for a long time! |

|||||||

|

|||||||

| Bobby Hartness (back to top) |

|

.jpg) |

.jpg) |

.jpg) |

.jpg) |

.jpg) |

.jpg) |

.jpg) |

.jpg) |

.jpg) |

.jpg) |

.jpg) |

.jpg) |

.jpg) |

.jpg) |

.jpg) |

.jpg) |

.jpg) |

.jpg) |

(back to top)

Wayne's workshop is located on the lower level of his home, over-looking his back yard. As you may notice, his floor is fully carpeted and his two dogs (in various pictures) seem to enjoy this amenity. He also has an integrated dust collection system that is serviced through a cyclone system, located in an area separate from the workshop. Note the 25 to 28 year-old Sears Craftsman radial arm saw, still functioning well.

|

|

|

|

|

|

|

|

|

|

(back to top)

This is the shop addition. The double door on left is for a tractor. Overall shop dimensions are 30' x 32', including 11' x 8' for tractor. The ceiling is 11'. |

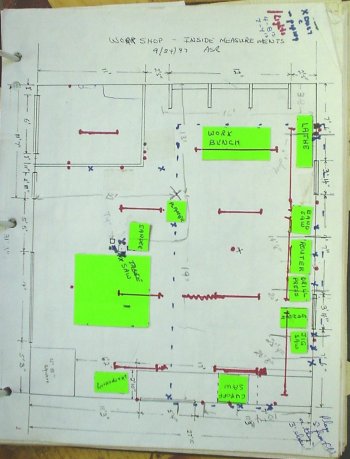

Layout plan |

Wood storage: 16' wide, 2' deep, 9' high |

Exotic storage |

|

Jointer (left) and table saw (above) positioned to make use of door locations for long pieces. |

Table saw extension table. |

Table-saw table |

Wide belt sander |

Spraying stations. From right to left: turbine/compressor, spray-gun and holder, turntable, drying rack. |

Clamp storage |

Scroll saw |

Drum sander |

Drill press |

Router table |

Some of Aubrey's work. The picture below the cabinet is of his father in the engineer's seat. |

Bandsaw (Laguna 18") |

Bandsaw (Delta) |

Drill bits |

Band saw blade storage |

Workbench with vises |

Disc/belt sander |

Dust collector |

Lathe; note dust intake |

Storage cabinets |

Dust collector with filter |

More hand tools |

Compound miter saw, dust cavity, and hand tools. |

Hardware storage |

Finishing supplies |

Chop saw workstation |

Tormek sharpener |

More hand tools |

Work in progress: Big-Boy, using ebony |

Plywood storage, and clamps. |

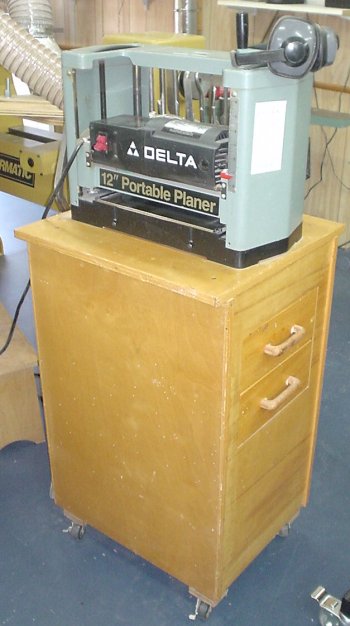

Thickness planer. All cabinets were made by Aubrey. |

1713 Queen Anne table reproduction |

Vacuum press, for veneering |